Portable, In-situ, Micron-level Roughness Measurement and Analysis

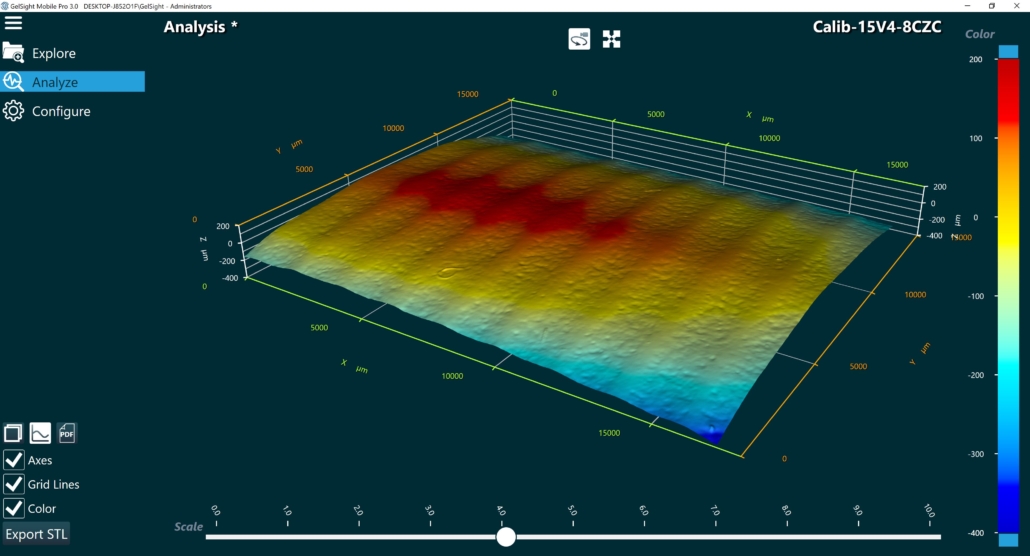

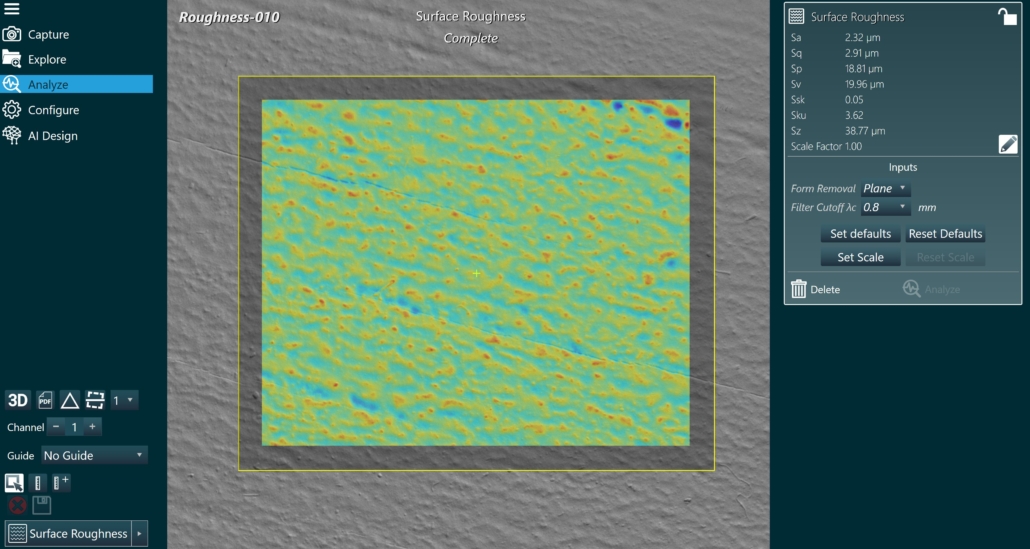

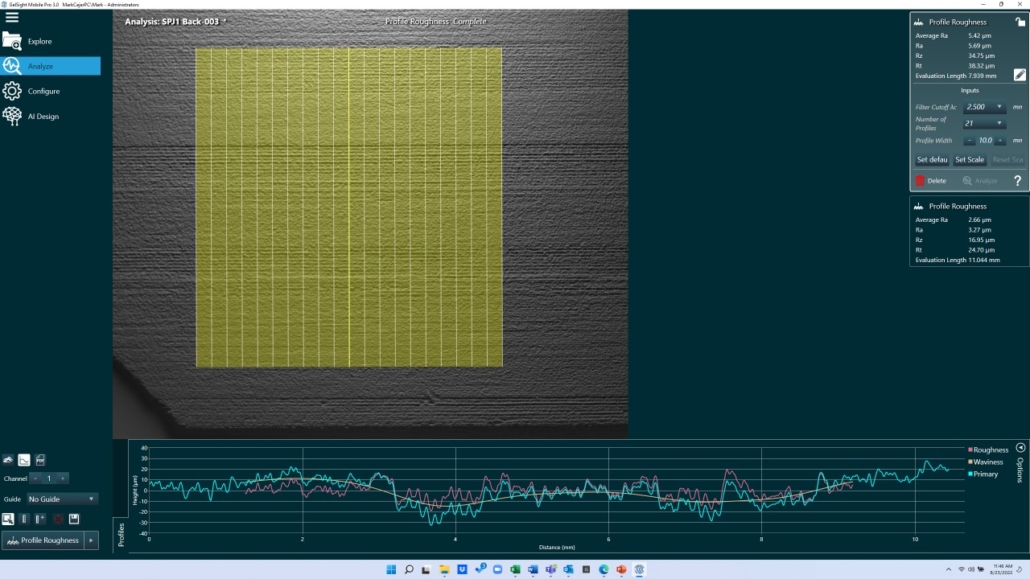

GelSight’s proprietary technology instantly captures 3D surface data at the press of a button, while offering industry-standard ISO and ASME analysis methods for both profile and surface roughness parameters. In-situ, precision surface analysis is achieved regardless of material type, reflectivity, or transparency.

Wide Range Of Use Cases

GelSight’s ability to analyze profile and/or surface roughness in-situ, on any type of surface in a single sample, significantly boosts productivity in a variety of R&D and production QC inspection applications, including:

- Metals, plastics, composites, glass, rubber, fabrics, natural surfaces, molds, and more.

- Coatings, films, paints, finishes, textures, and more.

- Applications requiring compliance with ISO 25178-2:2021, ISO 21920-2:2019, ASME B46.1.2019, or ISO 4287:1997 standards.